Challenge

Welding and arc-blasting required at heights typically means running cables and air hoses along platforms inside of a building under construction and resetting those cables and equipment as welders go from area to area, causing entanglement and safety issues and hurting team productivity. We knew there had to be a better way.

Solution

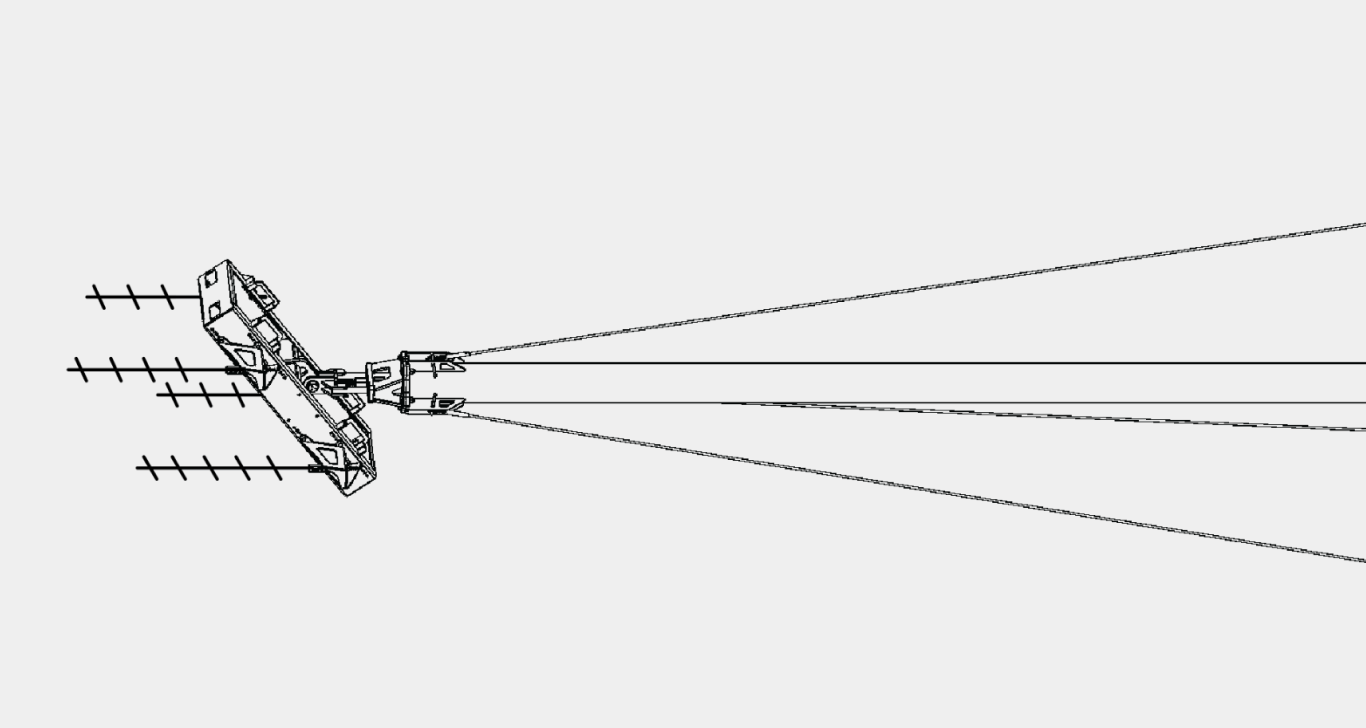

The WeldAir100, specifically designed for Snorkel boom lifts, consists of a framework with an inverter welder and an air compressor to provide welding and arc-blasting capabilities on-the-go. It mounts to the back of a boom lift, allowing equipment to travel with the machine, welding cables and air hoses are channeled to the operator in the lift platform for ease of use. This solution eliminates the risk of entanglement and dramatically increases safety and productivity.

“With the WeldAir100 we’re finally able to access welding points with all needed equipment at heights and on-the-move. It’s a game-changer.”